Conveyor Belts

We offer a wide range of conveyor belts for all types of applications such as:

-

Oil resistant

-

Hear resistant

-

Fire resistant

-

Abrasion resistant

In thickness and layers according to the clients application and width up to 2.400 mm

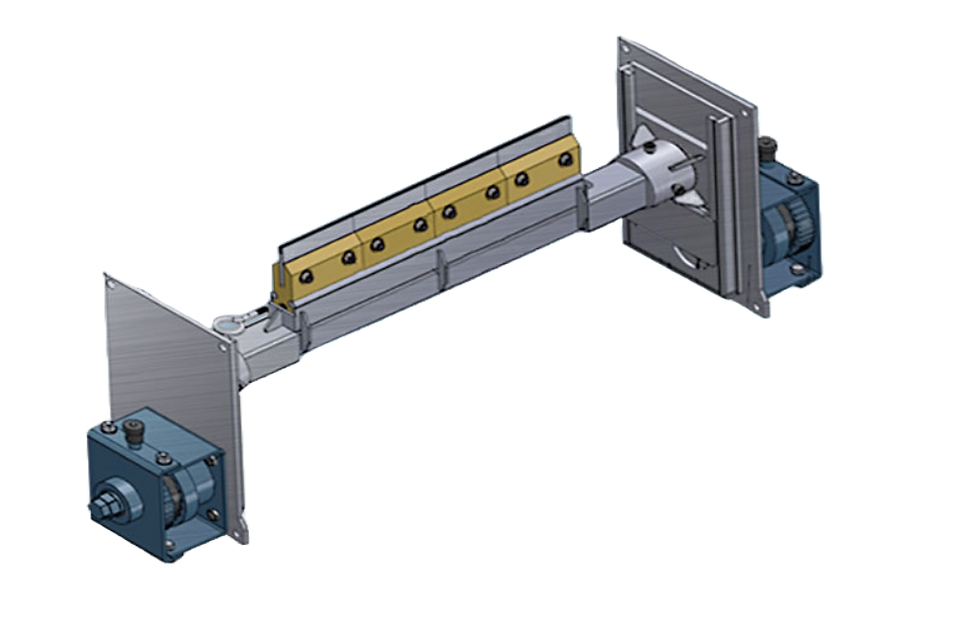

SIETHOM Belt Cleaner various models

Besides of the herein already described models of Belt Cleaners, SIETHOM has designed numerous further cleaner blade types for the primer and secondary scraper. The here shown variante is assisting by means of a steel blade to get a perfect cleaning result, but on the other hand due to both sides cover to protect the belt against scratching and damaging. This Variante also exists in Twin version.

SIETHOM’s Belt Cleaning System is based on years of field experience and feedback from clients regarding the weaknesses of competitor scrapers. Designed for both standard and extreme heavy-duty applications, it is ideal for use in quarries, mines, steel and cement plants, pelletizing and fertilizer plants, and more.

The system is especially effective with challenging materials like bauxite, wet coal, coal dust, sludge, and other sticky substances that are difficult to clean, such as cement, flour, and wheat bran. It also performs reliably with clinker, iron ore, and pellets, even under the toughest conditions.

Product range

MAXX STEELFLEX

Steeel Cord (ST)

MAXX STEELFLEX FB

with Textile Rip Stop Breaker

Top Cover

MAXX STEELFLEX IW/IWR

with Transverse Steel Breaker

Bottom Cover

MAXX STEELFLEX ROUND

Pipe Belts with steel cord reinforcment

Cross-Section

with Breaker

Steel Cord

Carcass

Belt Cleaning Technology

SIETHOM Primer

Several facts of our SIETHOM SHARK patented scrapers differ from market known scraper brands:

MODULAR DESIGN

Construction of the scraper in modular design.

PLUG SYSTEM

Design based on a PLUG system construction for easiest mounting and blade change.

NO SCAFFOLDING

Blade change allowed without scaffolding of the chute.

NO SPILLAGE

Chute wall can remain completely closed – no spillage.

SIETHOM secondary or main scraper

Several facts of our SIETHOM SHARK patented scrapers differ from market known scraper brands:

MODULAR DESIGN

Construction of the scraper in modular design.

PLUG SYSTEM

Design based on a PLUG system construction for easiest mounting and blade change.

NO SCAFFOLDING

Blade change allowed without scaffolding of the chute.

NO SPILLAGE

Chute wall can remain completely closed – no spillage.

SIETHOM Secondary or Main Scraper in Twin Design

The Twin design warrants a significant increase of the cleaning percentage and so is assisting together with the SIETHOM patented primer to reach a cleaning performance of avoiding CARRY BACK of almost 100%.

MODULAR DESIGN

Construction of the scraper in modular design.

PLUG SYSTEM

Design based on a PLUG system construction for easiest mounting and blade change.

NO SCAFFOLDING

Blade change allowed without scaffolding of the chute.

NO SPILLAGE

Chute wall can remain completely closed – no spillage.

Belt cleaner that are safer, cleaner and more productive in material handling

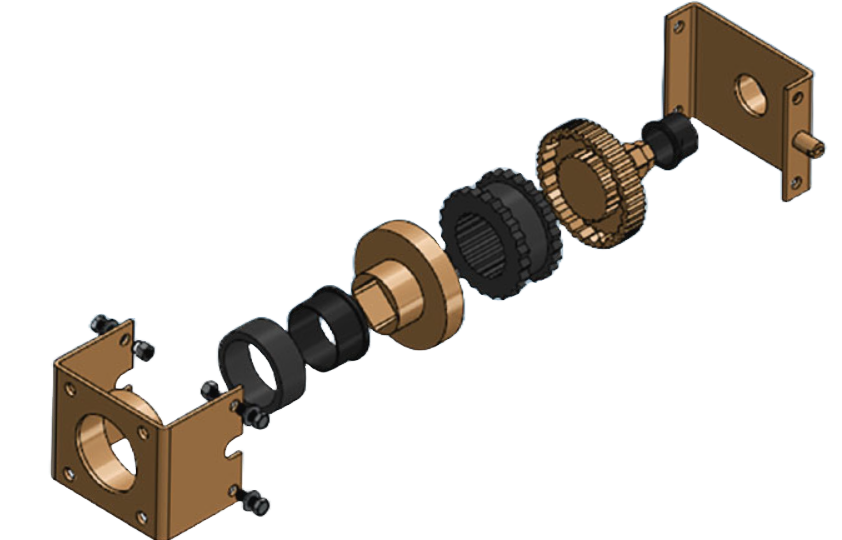

SIETHOM SENSTENS

SENSTENS is a proprietary name developed by SIETHOM, representing a unique "feeling-based" pre-tensioning system for scrapers. This technology enables precise tensioning through tactile feedback, activated by the controlled compression of elastic elements within the SENSTENS body, as detailed in SIETHOM’s European patent.

A key advantage of SENSTENS over conventional tensioning systems is its versatility—it is designed for use with both primary and secondary scrapers. Most notably, SENSTENS allows for a fully enclosed chute installation for both secondary scrapers and the TWIN SCRAPE system, enhancing safety and dust control.

Belts & Belt Cleaning

Features

-

Conveyer Belts steel cord & fabric - heat & oil resistent

-

Scraper lenght from 500 to 2400mm

-

Allowing closed chute including secondory scraper

-

Twin scraping on secondary available

-

Sensitive tension with SENSTENS

-

PU material including for high temperature applications

Applications

-

Mining industry

-

Cement industry

-

Coal industry

-

Bauxite material

-

Clinker

-

Aggregates

-

Oil & Petcoke

-

Sulfur

-

Fertliser

Advantages

-

Closed chute allowing

-

Easy change based pull out option

-

Less carryback based on twin solution

-

Continous tensioning with SENSTENS

-

Patented solution